Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

Curved conveyor belts revolutionize material transport, maneuvering smoothly around bends. Precise measurement ensures efficiency and prevents costly errors. In this post, you'll learn methods to measure curved belts accurately.

Curved conveyor belts are designed to move materials smoothly around bends and corners, fitting into spaces where straight conveyors can't. Unlike straight belts, these belts can bend horizontally, allowing them to change direction without stopping the flow. This flexibility helps optimize space in factories or warehouses by reducing the conveyor system's footprint.

One key feature is their ability to roll into a tubular shape during operation. This shape helps keep materials centered on the belt, reducing spillage and improving safety. The belts usually have strong lateral rigidity to maintain their shape while being flexible enough to bend around curves. Materials like nylon-polyester blends are common because they combine durability, elasticity, and resistance to wear, ozone, UV rays, and flexing.

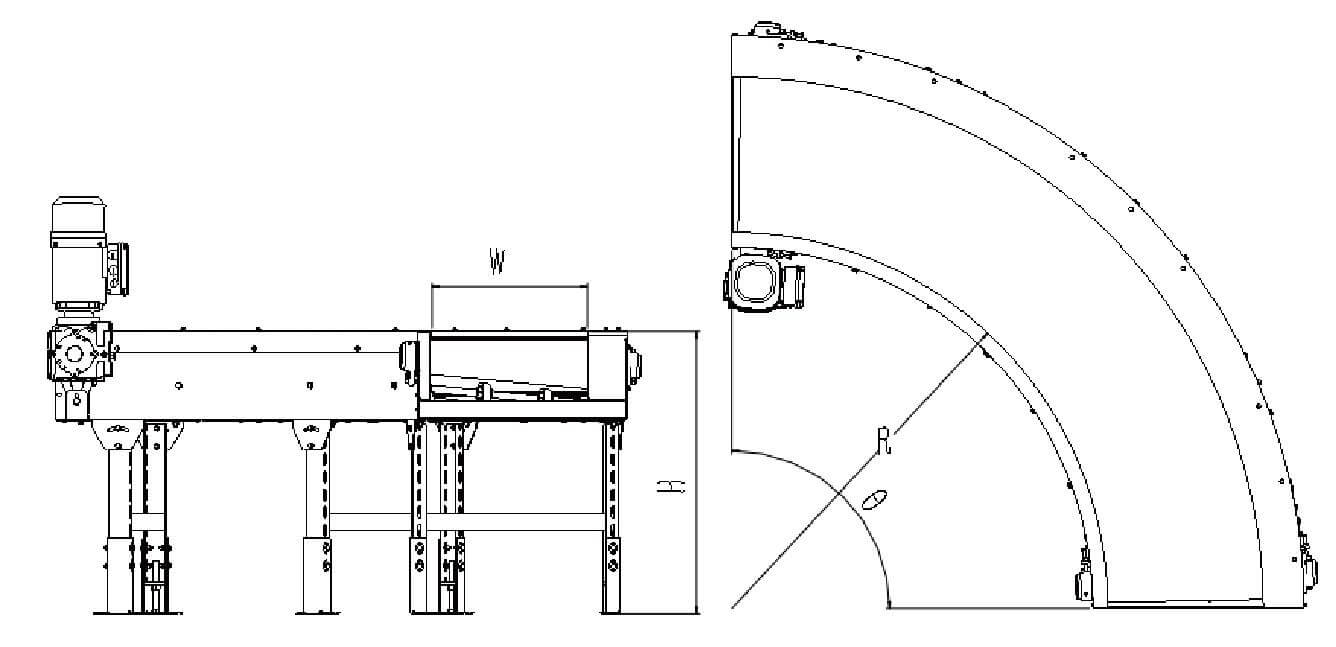

Curved conveyor belts also come with various bending types, such as horizontal bends, S-shaped bends, convex arcs, and concave arcs. Each type suits different layout needs and affects how the belt handles stress and tension. For example, convex arcs usually require a larger radius of curvature to prevent twisting and excessive wear.

Advantages include:

Space Efficiency: They fit conveyor paths into tight or irregular spaces.

Smooth Material Flow: The tubular shape helps keep materials centered and secure.

Durability: Designed to handle bending stresses without damage.

Versatility: Suitable for many industries and materials, from light packages to heavy bulk goods.

Curved conveyor belts are widely used across industries requiring efficient material handling in limited spaces or complex layouts. Here are some common applications:

Manufacturing: Moving parts between assembly stations when straight paths aren’t possible.

Food Processing: Transporting food items around corners while maintaining hygiene and preventing spillage.

Mining and Bulk Handling: Carrying heavy, abrasive materials through bends without belt damage.

Packaging: Redirecting packages and products efficiently through sorting and packing lines.

Warehousing and Distribution: Optimizing space by routing conveyors through corners and around obstacles.

Each application benefits from the belt's ability to maintain consistent speed and tension despite curves, ensuring smooth, continuous operation. Industries often select belts based on specific needs like load weight, environmental conditions, and required durability.

The type and material of the conveyor belt significantly impact how you measure its curvature. Curved belts are designed to roll into a tubular shape during operation, so they need proper lateral rigidity and flexibility. Materials like nylon-polyester blends are common because they balance strength and elasticity well. The belt's core material elasticity, often measured by its elastic modulus, directly affects the smallest radius it can bend without damage.

The outer and inner covers of the belt also play roles. The outer layer must resist weather, ozone, UV rays, and repeated flexing, while the inner layer needs excellent wear resistance. These properties ensure the belt maintains its shape and durability around curves. When measuring curvature, knowing the belt's material helps predict how tight the curve can be and guides the choice of radius.

The pipe diameter of a curved conveyor belt defines the belt width and influences the curvature radius. A larger pipe diameter means a wider belt, which affects the difference between the inner and outer arc radii in the curved section. This difference causes varying strain across the belt's width, with the edges experiencing more tension than the center.

Typically, the radius of curvature is proportional to the pipe diameter. Designers select pipe diameter based on factors like conveying capacity, belt speed, and the size of materials being transported. When measuring the curve, it's essential to account for the pipe diameter because it determines the minimum radius that the belt can handle without excessive stress.

Moreover, the layout design, including the shape of bends—such as horizontal, S-type, convex, or concave arcs—affects curvature measurement. For example, convex arcs usually require a larger radius to avoid twisting or damage. The layout must balance space constraints and mechanical limits, influencing how you measure and set the curvature.

Belt tension plays a crucial role in curvature measurement. The tension in the curved section is typically higher than in straight sections, leading to greater belt elongation. When tension is high, the radius of curvature must increase to reduce stress on the belt and the rollers. Smaller radii cause rollers to endure larger forces, which can shorten their service life.

Different bending types affect how tension and forces distribute across the belt. For instance, horizontal bends, S-shaped bends, convex arcs, and concave arcs each impose unique stresses. Convex bends often cause more twisting, so they require careful measurement and usually a larger curvature radius. Concave bends can handle smaller radii but still need precise tension calculations.

Measuring curvature must consider these bending types and the tension present. Adjustments in the radius may be necessary to ensure the belt operates smoothly without damage. Calculations often use formulas or tables that recommend minimum radii based on belt type, tension, and bending form.

One of the most reliable ways to measure a conveyor belt, especially for simpler systems with two pulleys, is the center-to-center distance formula. It calculates the belt length based on the distance between the centers of the drive pulley and the tail pulley, plus the pulleys’ diameters. The formula looks like this:

L=2C+π×2D+d+4C(D−d)2

Where:

L = belt length

C = center-to-center distance between pulleys

D = diameter of the larger pulley

d = diameter of the smaller pulley

π ≈ 3.1416

This formula accounts for the belt wrapping around the pulleys and the straight sections between them. It’s important to measure the center-to-center distance accurately. Use a tape measure or laser distance tool for precision. Also, note the pulley diameters carefully, as even small errors affect the final belt length.

If your conveyor system has adjustable take-ups, remember that moving the take-up changes the center distance and thus the belt length. For example, moving the take-up 5 inches outward adds 10 inches to the belt length, since the belt length changes by twice the take-up movement.

For curved conveyor belts with multiple pulleys or complex layouts, the center-to-center formula won’t work. Instead, use the start and stop technique:

Mark a starting point on the belt’s top surface and label it "0."

Find the furthest accessible point along the belt and mark it. Measure the distance between "0" and this mark.

Jog the conveyor so the second mark moves to the original "0" position. Mark a new point at the furthest accessible spot again.

Repeat this process, measuring between marks each time, until the belt completes a full loop back to the original "0" mark.

Add all measured distances between marks. The sum is the total belt length.

This technique requires two people for safety and accuracy. Always ensure no body parts or tools are on the belt when jogging it. This method works well for curved belts because it follows the actual path the belt takes, including any bends or curves.

Accurate measurements are crucial. Even small errors can cause problems like:

Ordering a belt that’s too short or too long

Increased downtime during belt replacement

Higher costs due to reordering or adjustments

Reduced conveyor efficiency

Use reliable measuring tools and double-check all dimensions. When measuring pulleys, measure diameter at multiple points to confirm roundness and accuracy. For center-to-center distances, measure carefully along the conveyor frame or use laser distance meters for better precision.

Also, consider belt tension and take-up positions. If the tensioner is fully extended or retracted, it affects the belt length needed. Adjust take-ups to a neutral position before measuring, if possible.

In complex conveyor layouts, consult manufacturer specifications or use specialized software for belt length calculations. These tools often incorporate belt curvature, pulley sizes, and tension factors to provide precise measurements.

Measuring a curved conveyor belt often involves dealing with physical obstacles. Terrain variations like slopes, uneven ground, or hills can make it tricky to get precise measurements. Buildings, columns, or other structures near the conveyor path may block direct access, forcing you to estimate distances or angles rather than measure them straightforwardly.

These interferences can lead to errors in determining the actual curvature radius or the belt path length. For example, if a conveyor must curve around a support pillar, the curve radius might need adjusting to fit the space, affecting measurement accuracy. In such cases, you may have to:

Use indirect measurement tools like laser distance meters or total stations to capture distances around obstacles.

Break the curved section into smaller segments, measure each separately, then combine results.

Rely on detailed layout drawings or 3D models to supplement physical measurements.

Planning measurements during times with minimal activity around the conveyor helps reduce risks and allows better access. Also, documenting any adjustments made due to terrain or building constraints is essential for future reference.

Belt tension significantly impacts curved conveyor belt measurements. When a belt is under tension, it stretches slightly, altering its effective length and curvature. Take-up assemblies, which maintain proper tension, can be adjusted during operation, changing the center-to-center distances and belt length dynamically.

If you measure the belt while the take-up is fully extended or retracted, your results might not reflect the belt’s typical operating length. To handle this:

Adjust the take-up to a neutral or mid-position before measuring. This position represents average operating tension.

Note the current take-up setting during measurement, so you can calculate any length changes needed if the take-up moves later.

Use formulas that account for take-up adjustments. For example, moving the take-up by distance X changes the belt length by approximately 2X.

Belt tension also affects the curvature radius. Higher tension requires a larger radius to avoid excessive stress on the belt and rollers. When measuring, consider the tension state and, if possible, measure under normal operating conditions rather than when the belt is slack or overly tight.

Measuring a curved conveyor belt on your own can be tempting, especially when you want to save time and money. However, there are several factors to keep in mind before deciding to do it yourself.

First, curved conveyor belts often have complex layouts with multiple pulleys and bends. This complexity makes accurate measurement tricky. Without proper tools, such as laser distance meters or flexible measuring tapes, you might end up with inaccurate lengths or curvature radii.

Second, safety is a major concern. Conveyor belts can be heavy and sometimes operate in tight spaces or near machinery. Measuring while the conveyor is running is dangerous. Even when stopped, accessing all parts of the belt, especially in industrial settings, can be challenging.

Third, belt tension and take-up assemblies influence measurements. If you measure when the belt is slack or overly tight, your results won’t match operating conditions. Adjusting take-ups to a neutral position before measuring is crucial but can be difficult without experience.

Fourth, DIY measurements require patience and precision. Small errors in measuring pulley diameters, center-to-center distances, or the belt path length can cause significant problems. Ordering a belt too short or too long leads to downtime and extra costs.

Finally, consider the tools you have. Simple tape measures might work for short, straight sections but fall short on curves or multi-pulley systems. The “start and stop” technique for multi-pulley belts requires at least two people and careful coordination.

Hiring professionals to measure your curved conveyor belt offers several advantages that often outweigh the costs.

Experts have specialized tools and experience. They use laser distance meters, digital calipers, and software designed for conveyor systems. These tools help them capture precise measurements, even in complex or obstructed layouts.

Professionals understand belt tension, take-up adjustments, and curvature requirements. They can measure under normal operating conditions or simulate them, ensuring the belt length and radius match real-world use.

They also know how to navigate safety hazards. Professionals follow strict protocols to avoid accidents, especially when measuring in active industrial environments.

Moreover, professionals can provide consultation beyond measurement. They can recommend optimal belt types, curvature radii, or layout adjustments to extend belt life and improve efficiency.

Using professional services reduces the risk of ordering incorrect belts, which saves time and money. It minimizes conveyor downtime and prevents costly mistakes during installation.

In many cases, manufacturers or specialized conveyor service companies offer measurement and installation services as a package. This integrated approach ensures the belt fits perfectly and performs reliably.

Choosing between DIY and professional measurement depends on your conveyor’s complexity, available tools, safety considerations, and budget. For simple, accessible systems, DIY might suffice. For complex or critical operations, professional help often proves invaluable.Curved conveyor belts, essential in modern material handling, require precise measurement for effective use. Key points include understanding belt type, tension, and layout design. Accurate measurement techniques, such as the center-to-center distance formula and start-stop method, ensure proper belt length and curvature. Professionals offer expertise and tools for complex systems, enhancing precision and safety. Zhejiang Rigor Logistics Technology Co., Ltd. provides high-quality curved conveyor belts, ensuring durability and efficiency, making them a valuable choice for various industries.

A: Curved conveyor belts efficiently move materials around bends, optimizing space in factories and warehouses.

A: They roll into a tubular shape during operation, keeping materials centered and secure.

A: Nylon-polyester blends are common due to their durability, elasticity, and resistance to wear and environmental factors.

A: Professionals ensure precise measurements, safety, and optimal belt performance, reducing risks and costs.